For All Enquiries 1(775) 324 2400 - Sales 24/7 1(877) 540 4154

Espanol (Cesar Medina) 1(877) 540 4154

Bookmark

Bookmark

Proposal for G.A.* Regarding Water Treatment Systems

(*name removed for privacy reasons)

The following proposal was prepared for Ionlife and later on accepted by customer for use on a US dairy farm.

It is presented here as an example of Ionlife capacity to deal with almost any type of water condition and provide a solution that is in keeping with the latest Japanese research.

(Please see article on "Alkaline Water for Japanese Dairy Cows" )

CONDITIONS:

G.A. consumes approximately 1,000 gallons per day of water for livestock and human consumption. Water quality is at acceptable levels with the exception of extremely high Total Hardness and elevated Nitrate Nitrogen.

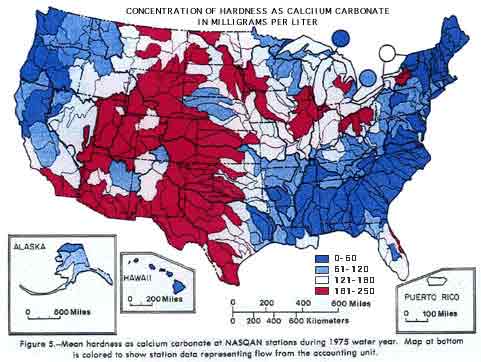

Total Hardness is the most common problem due to calcium and magnesium deposits that are naturally dissolved from the soil into water supplies. The Water Quality Association considers water to be"hard" when levels exceed one grain per gallon. To provide the public with a feel for the severity of the problem, the United States Geological Survey developed the following graphic showing Total Hardness levels throughout the US. To put the severity of G.A.'s problem into perspective, the red areas on the map indicate levels from 181-250 ppm and G.A. has hardness levels of 436.13!

Nitrates and nitrites are nitrogen-oxygen chemical units which combine with various organic and inorganic compounds. Once taken into the body, nitrates are converted into nitrites. Excessive levelsof nitrate in drinking water have caused serious illness and sometimes death. The serious illness in infants is due to the conversion of nitrate to nitrite by the body, which can interfere with the oxygen-carrying capacity of the child's blood. This can be an acute condition in which health deteriorates rapidly over a period of days. Symptoms include shortness of breath and blueness of the skin. Nitrates and nitrites have the potential to cause diuresis, increased starchy deposits and hemorrhaging of the spleen. The most common use of nitrates is as in fertilizer manufacturing.

OBJECTIVE:

Provide trouble free, cost effective solutions to meet the water quality objectives outlined above. G.A. has also expressed an interest in adding new, high volume ionization technologies now available. Ionized water will be used for both human and livestock consumption.

TREATMENT OPTIONS:

Ion Exchange (I/E) and Reverse Osmosis treatment are the only real cost effective options for hardness reduction. Both processes physically remove the calcium and magnesium ions from the water supply but employ different means to accomplish their goal.

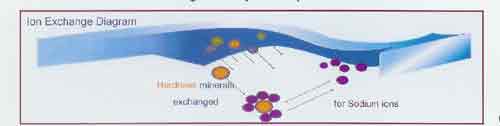

Ion Exchange technology utilizes plastic resin beads that have the ability to hold sodium ions, but prefer hardness minerals such as calcium and magnesium.  As the hard water flows over the beads, calcium and magnesium ions are captured and sodium released, thus the name "ion exchange". Eventually the plastic beads exhaust their ability capture any additional sodium, so recharging is needed.

As the hard water flows over the beads, calcium and magnesium ions are captured and sodium released, thus the name "ion exchange". Eventually the plastic beads exhaust their ability capture any additional sodium, so recharging is needed.

To recharge the beads, bags of salt are poured into a brine tank and mixed with water.

The saline brine is fed into the vessel storing the beads and the calcium and magnesium that was previously captured on the beads is then flushed into the sewer system. Once the regeneration process is complete, the beads are rinsed and then placed back into service and the ion exchange process begins all over again. In some areas of the US, municipalities are discouraging the use of water softeners due to the impact on sewer systems. Removing the sodium brine from sewage is expensive when trying to reuse the water for irrigation purposes on water reclamation projects, which is growing dramatically in water short areas. The downstream impacts of water softeners, required maintenance and, most importantly, its inability to remove nitrates make this technology infeasible for G.A.

Reverse Osmosis

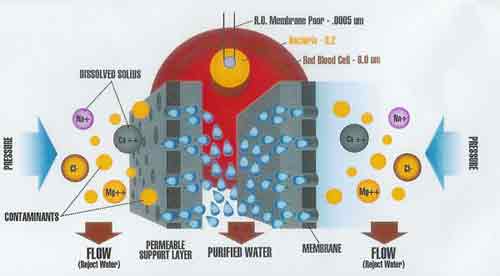

(R/O) technology consists of a semi-permeable membrane that physically filters out hardness. The membrane has small holes/pores that are sized to filter out approximately 98% of ALL suspended material in water. The membranes require pressure to force water through it, and have relatively low flow rates. On large scale systems, additional pumping is often required. The membrane also cleans itself automatically and sends water to a drain that must be provided. The water quality of the drain flow is very clean in comparison to sodium based ion exchange systems. To extend the life of the membrane, sediment and carbon filtration is provided as a pre-filter. Most importantly, R/O is an effective method for nitrate and nitrite removal.

Water Ionizing Technologies

Water ionizing technologies and their wide variety of health benefits, have been known for over 30 years in Japan. Starting at birth, our bodies are continuously trying to dispose of acidic waste caused by stress, air pollution and 98% of all food consumed. Smoking, consumption of red meat and egg yolks are just a few specific examples of actions that create high volumes of acidic waste.

Unless all acid consumed is eliminated through breathing, sweating (exercise) or urinating, it begins to build up in our blood. Increased acid cannot be tolerated in our blood, so the body uses homeostasis to control it. Excess acid is transformed in our bodies to a solid resulting in a build up of fatty acids (body fat), cholesterol and uric acid (kidney stones) as we age.

Unless all acid consumed is eliminated through breathing, sweating (exercise) or urinating, it begins to build up in our blood. Increased acid cannot be tolerated in our blood, so the body uses homeostasis to control it. Excess acid is transformed in our bodies to a solid resulting in a build up of fatty acids (body fat), cholesterol and uric acid (kidney stones) as we age.

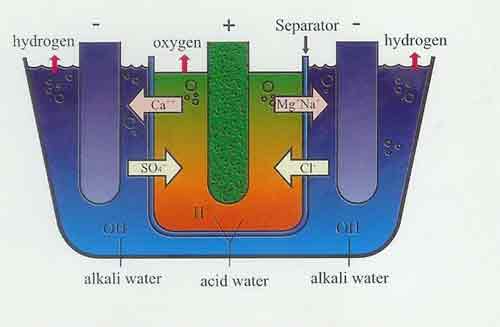

Continued acid build up will affect all of us differently. Based on our genetics, the acid will attack specific areas of the body possibly contributing to cancer, diabetes and other serious illness. One potential way to counteract the acid build up is to consume foods rich in alkaline minerals and drink alkaline water produced by an ionizer. Large scale ionizers are now available that can produce 1,000 gallons per day. Ionizers adjust the pH of drinking water by applying positive and negative charges on opposite sides of an electrolysis chamber. As the h2O molecule passes through the chamber, the positive hydrogen ion is diverted to the acidic side, and the negative hydrogen ion and the oxygen molecule (OH-) diverted to the alkaline side. The unique combinations of Oh- ions act as a powerful antioxidant and flood the body looking for acidic (positively charged) ions. When acid is found the OH- combination creates a water molecule again and is flushed out of the body.

SYSTEM RECOMMENDATIONS:

Based on all factors considered in the previous sections, a large scale R/O system is the preferred method of hardness and nitrate removal. Fortunately, not all water needs to be treated with R/O to get hardness and nitrates to reasonable levels, so a set of valves and storage tanks will be used to divert a portion of the incoming water around the R/O system. A carbon and sediment filtration system will be used to pretreat all water coming into G.A. Approximately 1/3 of the flow will be diverted around the R/O and blended in downstream resulting in water that does not have excessive hardness and nitrates any longer.

Also, the carbon-only treated water will also provide the desired level of minerals needed for water ionization. The proposed configuration will meet all of our water quality objectives.

R/O Treatment System

will provide enough capacity to treat the full 1,000 gallon per day.

The 1,000 gallon per day system retails for $6,400 and the Ionlife price is $3,999.

Additional metering, valving and storage tanks will be needed,

but a site specific design must be completed first to determine actual cost of this portion of the project.

Carbon Treatment System

proposed will provide approximately 75 gallons per minute of great tasting water to blend back in with the R/O treated water. The retail price for these systems is $2,299 with $400 in filters included.

proposed will provide approximately 75 gallons per minute of great tasting water to blend back in with the R/O treated water. The retail price for these systems is $2,299 with $400 in filters included.

This portion of the project will cost $1,799. Each set of filters will provide treatment for approximately 150,000 gallons, and should last approximately 6 months to treat all incoming water.

Commercial Sized Ionizer

will provide long term operation with consistent pH control and total automation and easy maintenance. Its high quality construction is designed for durability to withstand adverse conditions such as dust and high humidity. Retail price for the ionizer is $14,500 and the Ionlife price is $11,999. Dairy is an excellent application for ionized water as cows are healthier, provide increased milk production and have a longer milk producing life.

Project Cost Estimate

R/O System. . . . . . . . . . . . . $3,999

Carbon System. . . . . . . . . . $1,799

Ionizer System. . . . . . . . . .$11,999

Equipment Subtotal. . . . . $17,797

Design, Piping, Metering

(35% estimate). . .$6,300

Installation (20% est.) . . . .$3,600

Total Cost Estimate $27,697

Prices in this proposal will need to be re-evaluated following completion of system design. Completion of the project would require approximately 45 days from project authorization. If all or a portion of this project are authorized, a 50% deposit will be required upon initiation of contract, 25% upon delivery of equipment to the site and the final 25% upon completion of the project.

Any claims made regarding the benefits of ionized water have not been evaluated by the Food and Drug Administration, nor are we claiming to diagnose, treat, cure or prevent any disease.

Alkaline water and Dairy cows

AlkaViva Models Compared

Consumer Buying Guide and Checklist

Home Page